TYPE OF WHEEL, PROCESSING AND COST PER PIECE DETERMINE THE CHOICE OF THE DIAMOND TO USE

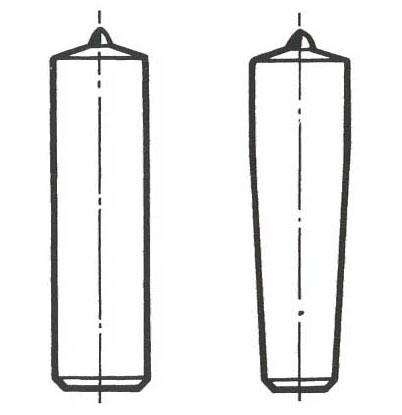

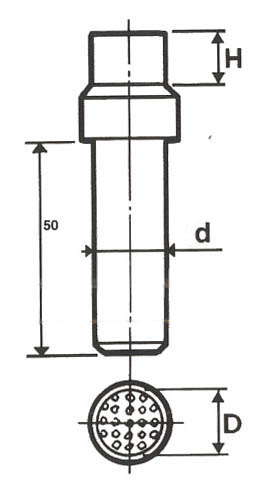

1) SINGLE POINT DRESSERS

Dressers are essential to dress wheels; they can also give the shape to the abrasive ones.

DETAILS

In this section there are technical designs, their features and stock products.

It's possible to request special processing and sizes.

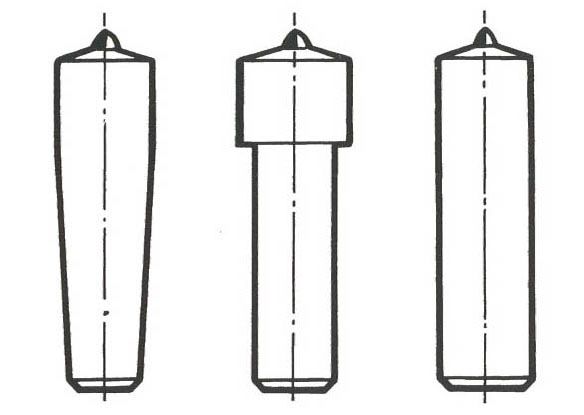

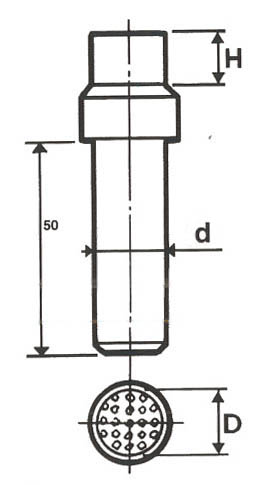

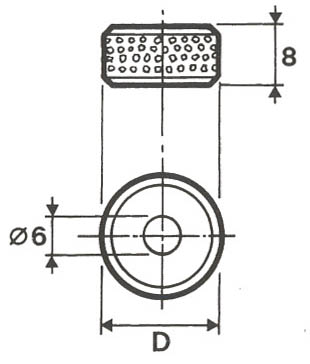

2) MULTIPLE DIAMOND DRESSERS

Dressers on stem and roll with selected high quality diamond.

DETAILS

In this section there are technical designs, their features and stock products.

It's possible to request special processing and sizes.

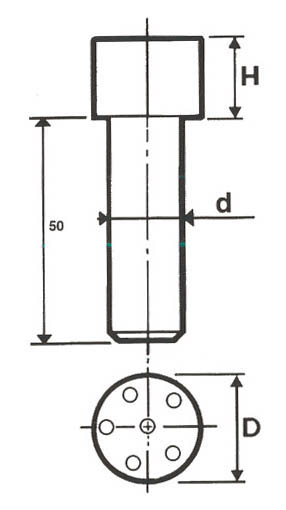

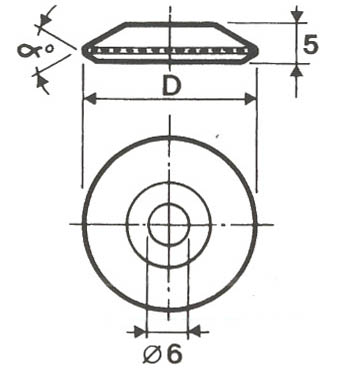

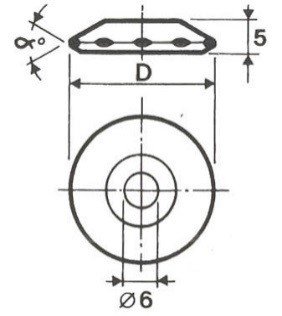

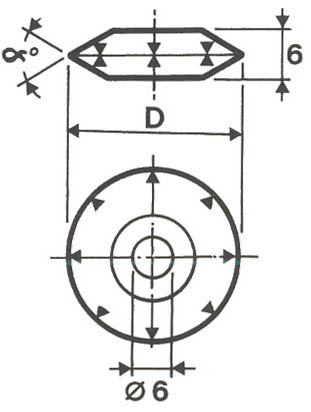

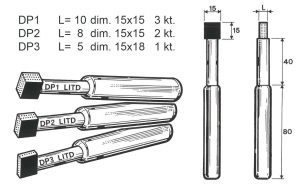

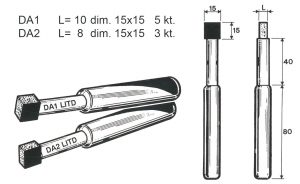

3) CIRCULAR DRESSERS AND HAND GRINDING WHEEL DRESSERS

Multiple diamond circular dressers have needle-like diamond positioned in a continue way on a single row, natural selected with natural corners or sharpened synthetic.

Hand grinding wheel dressers are on positioned diamonds (DP) or agglomerated grains (DA).

DETAILS

In this section there are technical designs, their features and stock products.

It's possible to request special processing and sizes.

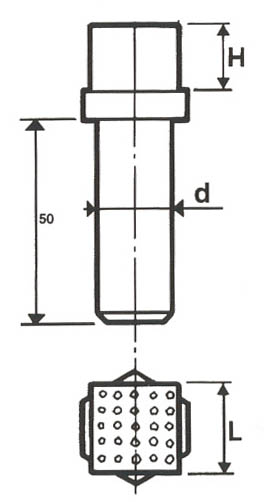

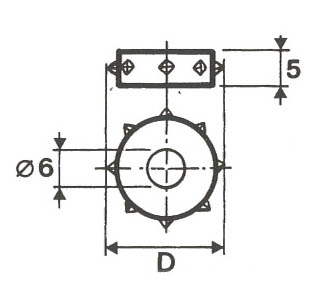

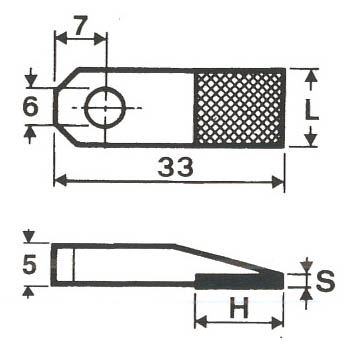

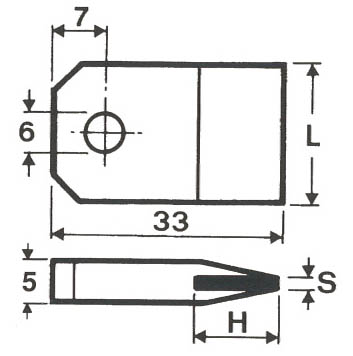

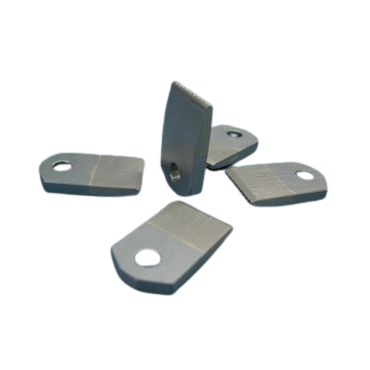

4) DIAMOND PLATES AND MACHINED DIAMOND TOOLS

Diamond plates are RTL or RTC type, on positioned diamonds or agglomerated grains.

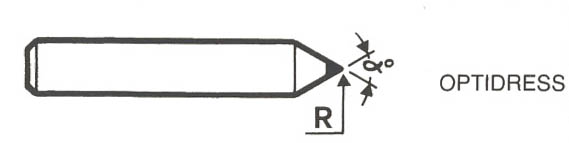

Machined diamond tools are Diaform type ("chisel" machined) and Optidress type ("cone" machined).

DETAILS

In this section there are technical designs, their features and stock products.

It's possible to request special processing and sizes.

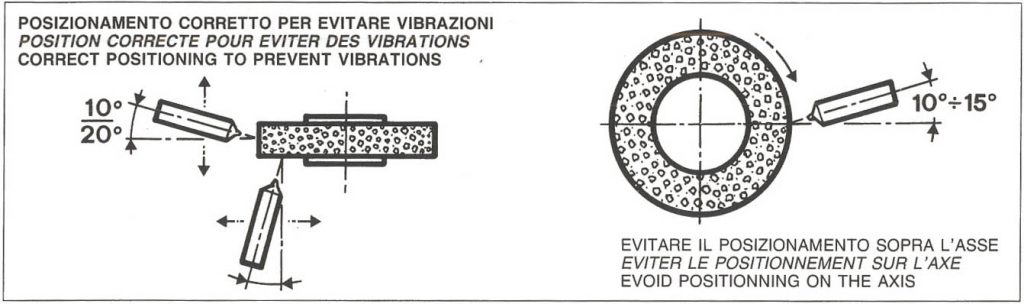

USAGE RECOMMENDATIONS

For a correct use of the tool, follow these information:

- Open the refrigerant spout before the touch between diamond and wheel

- Medium cut depth: 0,03 mm

- Maximum cut depth: 0,05 mm

- Fast cut speed: for roughing applications

- Slow cut speed: for superfinishing applications and on hard wheels